Laser Materials and Optics (LMO)

Summary

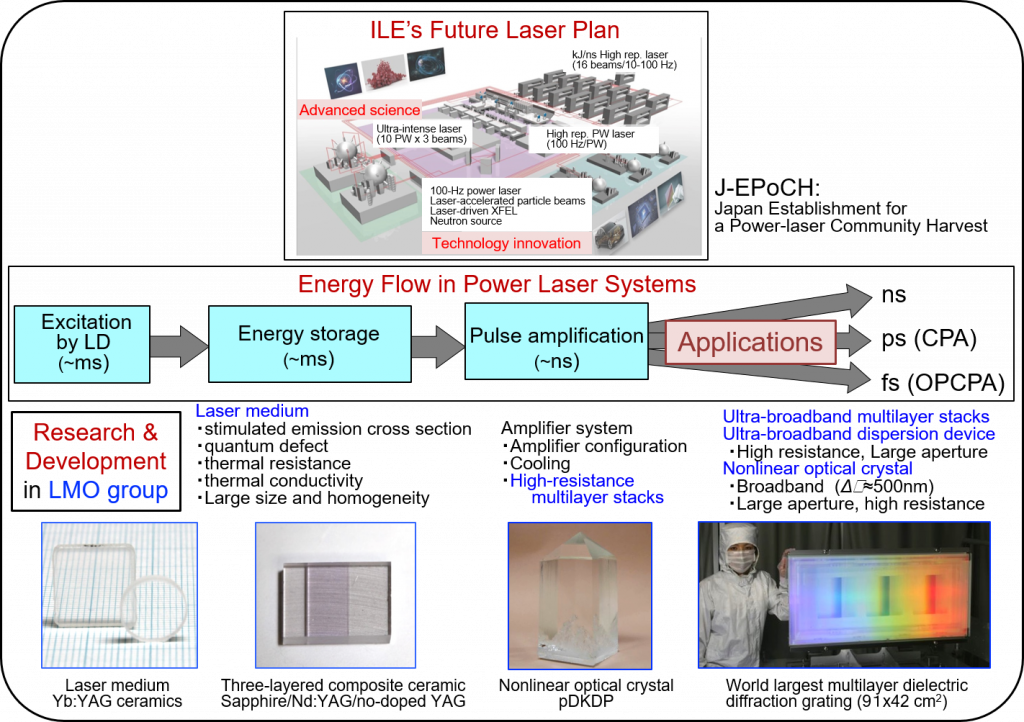

It is necessary to improve the efficiency and functions of high-power lasers which is the source of international competitiveness in the field of laser science. LMO Group is challenging the development of optical elements such as new laser materials and multilayer-coated devices which are the basis for realizing advanced lasers. Specific research subjects are transparent ceramics and their application to optical functional materials, nonlinear optical crystals for the broadband wavelength conversion, special optical fibers, broadband multilayer devices (mirrors and diffraction gratings) and the elucidation of laser damage mechanism for the further improvement of laser damage resistance of optical elements.

Research topics

1.Development of optical materials and devices for high-power lasers

-

Fabrication of ceramic laser materials and composite technology

Based on an original technology for producing transparent ceramics, we are fabricating the yttrium aluminum garnet (YAG) added with rare earth elements such as ytterbium (Yb), neodymium (Nd) and cerium (Ce). We are also developing new laser materials co-doped with optimized concentrations and the bonding technology for ceramic/ceramic composite and ceramic/sapphire composite, etc.

-

Deuteration ratio control and rapid growth of KDP crystal

ILE developed the fabrication technology of large-aperture KDP crystal for the frequency doubling (green) and tripling (UV) of Nd:glass laser fusion driver. Such an optical parametric process can be used for the amplification of near infrared laser pulse by the pumping by green laser pulse. We showed 500-nm bandwidth of an optical parametric amplification by optimizing the deuteration ratio of KDP crystal. In addition, a method for rapid crystal growth (several cm/day) have been developed to fabricate large crystals which is one of key elements to realize exawatt peak power (1 EW = 1018 W) using the optical parametric amplification.

-

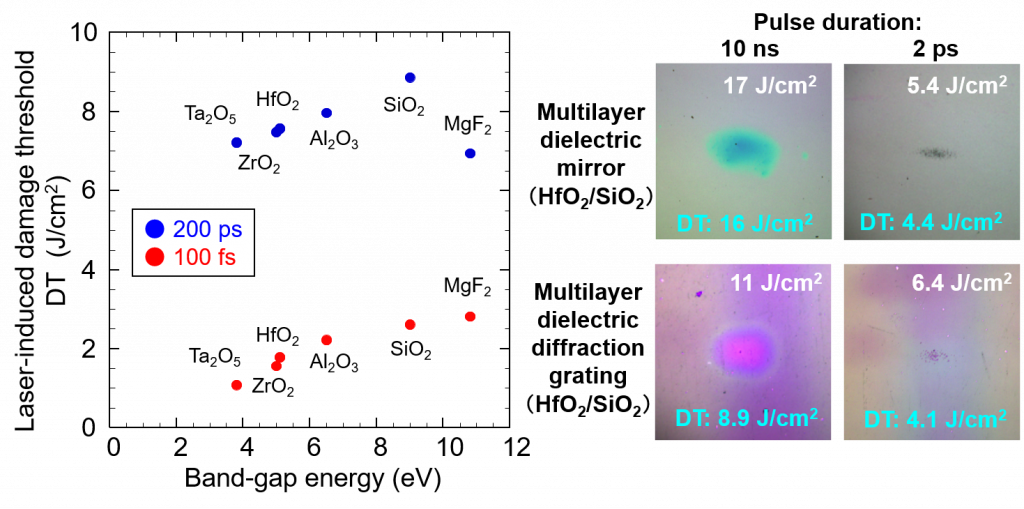

Developments of ultra-broadband large diffraction grating, polarizer and ultra-broadband, low-dispersion mirror

We have developed 1 m-class multilayer dielectric diffraction grating for LFEX PW laser. We are advancing this research to expand the diffraction bandwidth up to more than 100 nm and to improve the coating thickness accuracy of 1 m-class thin-film multilayer polarizer. We are also designing a low-dispersion mirror and chirped mirror with an ultra-broad bandwidth. In addition, new dielectric materials useful for both broadband multilayer and high laser damage resistance are being developed.

Future power laser plane and research and development in LMO group

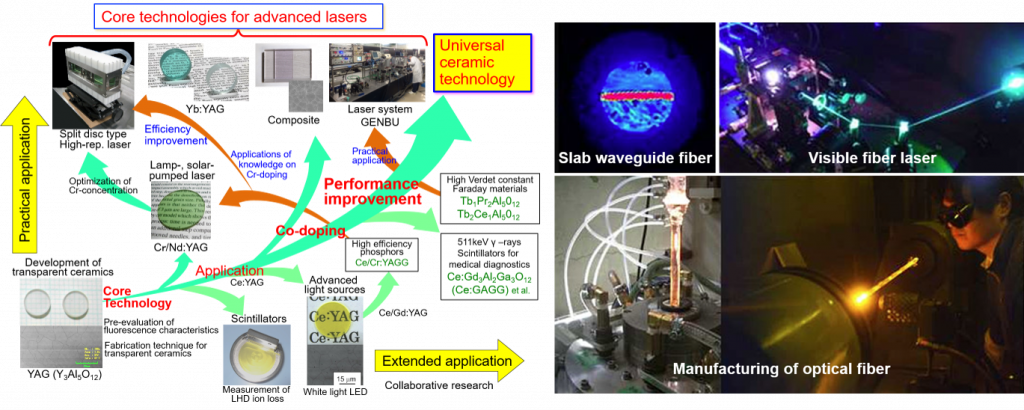

2.Development of optical functional materials and devices for industrial application

We are developing new functional optical materials by adding various elements to metal oxide ceramics. For example, high-performance scintillators for medical imaging diagnostics, high-sensitivity magneto-optical materials for Faraday rotator, and white light source materials for various kinds of illumination, etc. are being studied in collaboration with other research institutes. Photonic crystal fibers and optical fibers with special core structure are also being developed in collaboration with another university and company using the only fiber drawing apparatus existing in domestic universities.

Left: Applied research on transparent ceramics. Right: Fiber laser technology.

3.Development of method for damage evaluation and elucidation of laser damage mechanism

The laser-induced damage and lifetime shortening of optical devices have become one of utmost important issues as the peak power and repetition rate are currently increasing more and more. We are constructing a database on the relationship of the laser damage threshold to laser conditions (wavelength, pulse width, repetition frequency) and material properties of optical devices (compositions of coating material and their combination in multilayer stack, morphology, impurity, surface roughness and contamination of substrates, etc.) with the understanding of physics mechanisms of laser-induced damage process. Based on these databases and the knowledge of damage mechanisms, we are aiming to design multilayer stacks having high damage resistance.

Left: Relationship of laser damage threshold to material and pulse width. Right: Damage evaluation of multilayer reflector and diffraction grating

Member

| FUJIOKA Kana | Associate Professor |

| JITSUNO Takahisa | Specially Appointed Professor |

| MOTOKOSHI Shinji | Guest Professor |