Glass Laser System Operation and Development (GOD)

Summary

GOD is a set of groups for large laser facilities in the technical division. It consists of four groups for operation and development of Gekko-XII laser, LFEX laser, Plasma diagnostics instruments, and target fabrication.

Research topics

1. Gekko-XII laser : operation, maintenance , and development

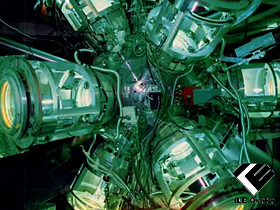

Gekko-XII laser system has a lot of laser components through which laser beams pass on the right axis with precise alignment of the beams. Laser parameters such as output energy, pulse shape, beam profile are monitored to keep the expected laser performance. The laser beams are frequency converted from infrared to green or ultraviolet light by KDP crystals just before the target irradiation. Various parts in the system are continuously developed and improved to enhance the laser performance.

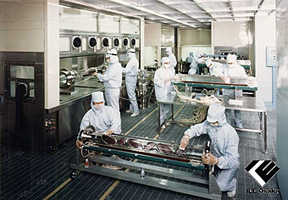

Gekko-XII has about 5000 optical elements such as mirrors and lenses with the size ranging from several mm to over 500 mm. These optical parts must be replaced when damaged or degraded by aging. Optical parts are carefully inspected before installed in the system. The system has 29 rod amplifiers with a diameter of 25 mm or 50 mm, 24 disk amplifiers of 100 mm, and 36 disk amplifiers of 200 mm. The amplifiers are pumped by flash lamps, and thus are gradually stained and the output energy weakened. Such degraded components are took apart to pieces, and cleaned up in a class-100 clean room to assure the performance of Gekko-XII.

2. LFEX laser : operation, maintenance , and development

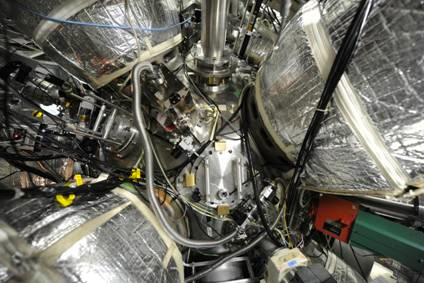

Oscillator part of LFEX laser system consists of a femtosec oscillator, a pulse stretcher with a pair of diffraction gratings, and three optical parametric chirped pulse amplifiers (OPCPA). LFEX group is working on operation, maintenance, and development of the system. LFEX laser is optically synchronized to the Gekko-XII.

Laser light delivered from the oscillator is further amplified in the pre-amplifiers and the main-amplifier system which consists of rod amplifiers, spatial filters, main amplifiers containing 46 cm x 81 cm x 4 cm glass slabs (LHG), and deformable mirrors. Optical alignment and wave-front correction in the beam pattern are carried out for every laser shot. Output energy, pulse width, spectrum, and wave front distortion are routinely monitored.

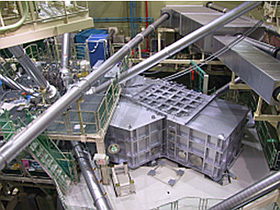

Four beams delivered from the amplifier chain are introduced to diamond-shaped pulse compressors installed in a vacuum vessel, pulse-compressed with two gratings per beam with the size of 42 cm x 92 cm, and brought to an off-axis parabola mirror, and finally focused in the target chamber.

3. Plasma diagnostics : operation, maintenance, and development

A variety of the plasma diagnostic instruments are used in the experiments. Some of those are developed by users, and some are developed, maintained, and operated to support the users as standard diagnostics by the plasma diagnostics group. Those are x-ray pinhole cameras, x-ray streak cameras, x-ray framing cameras, and so forth. The users are provided upon request with standard data such as spatial and temporal profiles of the plasma.

Target Chamber

Target irradiation by the laser beams are performed in the target chamber that consists of focusing lenses, target positioners, target monitor cameras, diagnostic ports, and vacuum pumps. Maintenance of the target chamber, particularly of the vacuum pumping system, is done regularly. The system is renewed in accordance to the long-term program.

Recently, x-ray imaging devices and fast-electron spectrometers compatible with intense hard x-ray backgrounds have been developed in collaboration with the users and introduced to the fast-ignition experiments. X-ray framing cameras coupled with x-ray mirrors and x-ray streak cameras with reinforced shielding were successfully developed and currently are powerful diagnostic capability in investigation of implosion and heating dynamics in the fast ignition experiments.

4. Target fabrication : development and supply

Development of the fast ignition targets has been promoted particularly in forming a uniform layer of the solid deuterium fuel inside the shell target. Targets with various structures and materials have been proposed. Fabrication technique to realize such targets is being developed.

Member

| ARIKAWA Yasunobu | Associate Professor |

| SHIGEMORI Keisuke | Professor |

| YOGO Akifumi | Professor |

| TSUBAKIMOTO Koji | Associate Professor |

| YAMANOI Kouhei | Associate Professor |

| YOSHIDA Hidetsugu | Specially Appointed Researcher |

| MATSUO Satoshi | Specially Appointed Researcher |

| OKU Hiroyuki | Technical Specialist |

| HASHIMOTO Kazuhisa | Technical Specialist |

| TAKAHASHI Keisuke | Technical Staff |

| YAMAGUCHI Chiyo | Technical Staff |

| HONDA Koichi | Technical Staff |

| KAWASAKI Tetsuji | Special case commissioned technical staff |

| MORIO Noboru | Special case commissioned technical staff |

| SAWAI Kiyonobu | Contract technical staff |